- info@jetway.co.uk

- 01225 742301

Process – Design & Machining

Our traditionally equipped machine shop enables us to offer a comprehensive service to our clients, a skilled and flexible workforce allows us to undertake ‘one-off’s’, small batch and higher volume production runs with confidence.

Our traditionally equipped machine shop enables us to offer a comprehensive service to our clients, a skilled and flexible workforce allows us to undertake ‘one-off’s’, small batch and higher volume production runs with confidence.

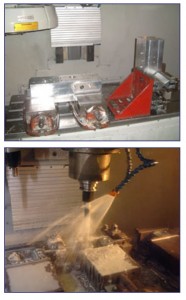

Milling

Bridgeport VMC 1000’s with Heidenhain controls permits us to undertake most milling operations including “thread milling”, automatic indexing and contouring. The versatility of the machine when combined with its Cad Cam facility reduces down time, speeds up programming and has proved ideal for both small and long running batch work. Bed size 1,000mm x 500mm.

Additional Vertical Milling capacity is provided by Bridgeport Interact Series 1 which also has the Heidenhain control package and although a very accurate machine the lack of a “tooling carousel” means it is more suitable for less detailed small batch work.

A range of standard Bridgeport’s, with Digital Readouts, probably the most versatile and widely used machines in engineering backs up and complements the CNC’s.

Horizontal milling seems to be somewhat in the decline these days but our reliable Tos Olomouc with its Anicanwizard control system, whilst not being the most up-to-date machine, remains sturdy, accurate and still achieves an amazing ‘metal removal rate’ when required. Bed size 1,400mm x 250mm.

Turning (Lathes)

We have a fairly comprehensive turning capacity covering both size and efficiency from the highly accurate Hardinge with its slide mounted indexing tooling turret to a Harrison, whose gap bed allows a 380mm diameter capacity complete with a 1,000mm bed length.

Colchester Triumph 2000 with Digital Readout and Harrison M250complete the range of centre lathes.

For repeatability we have the CNC Colchester fitted with the ‘Ez-path’ system that allows rapid programming and has a 50mm diameter bar capacity and has proven itself to be ideal for small to medium size batch production.

All lathes are fully equipped with a range of 3 jaw, 4 jaw, collet chucks and faceplates.

Turning (Capstans)

Emi-mec Auto Sprint 26’s add to our turning capacity, capable of accommodating up to 32mm diameter bar size, these workhorses produce accurate turned components throughout the day with the minimum of attention from their setter. Their capability of being fitted with pneumatic three jaw chucks make them ideal ‘second –op’ machines or even allows the machining of ‘billet’ or cast components.

Emi-mec Auto Sprint 26’s add to our turning capacity, capable of accommodating up to 32mm diameter bar size, these workhorses produce accurate turned components throughout the day with the minimum of attention from their setter. Their capability of being fitted with pneumatic three jaw chucks make them ideal ‘second –op’ machines or even allows the machining of ‘billet’ or cast components.

We still retain and operate a manual Toss capstan, principally because its ‘tooled-up’ for our own products, but it does occasionally come into its own for client works as its 55mm bar feed capacity adds to our overall capabilities.

Drilling / Tapping

Twin cast iron drill tables, each 1,500mm x 500mm and fitted with four ½” (12mm) and four 5/8” (16mm) capacity spindles, positioned end-to-end, provide an ideal platform for ‘jig drilled’ components. When fitted with drill chucks, reamers or tapping heads they allow a quick and inexpensive way of completing large batches of suitably jigged components.

Twin cast iron drill tables, each 1,500mm x 500mm and fitted with four ½” (12mm) and four 5/8” (16mm) capacity spindles, positioned end-to-end, provide an ideal platform for ‘jig drilled’ components. When fitted with drill chucks, reamers or tapping heads they allow a quick and inexpensive way of completing large batches of suitably jigged components.

Surface Grinding

A Jones & Shipman model 8-18 fitted with a 400mm X 150mm magnetic table completes or machine shop, used mainly for in-house tooling, we also offer a surface grinding service to our clients.