- info@jetway.co.uk

- 01225 742301

Process – Lean Manufacturing

What is Lean Manufacturing?

Lean manufacturing is defined as “a systematic approach to identifying and eliminating waste (non-value-added activities) through continuous improvement by flowing the product at the pull of the customer in pursuit of perfection” (Peterman, 2001, p. 24).

Lean manufacturing is defined as “a systematic approach to identifying and eliminating waste (non-value-added activities) through continuous improvement by flowing the product at the pull of the customer in pursuit of perfection” (Peterman, 2001, p. 24).

It is not really a new idea but it is one that has recently gained a great deal of attention.

Over the years, lean manufacturing has been referred to by different names, such as flow manufacturing, just-in-time production, demand flow technology and the Toyota Production System.

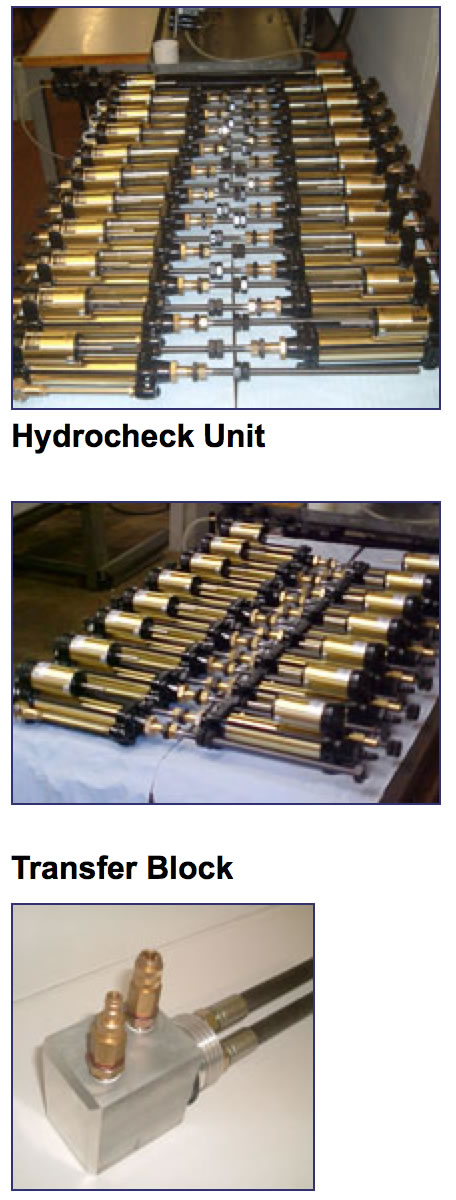

For a number of years Jetway Associates Ltd has been assisting an internationally known Plc to achieve its own Lean Manufacturing activities. Working in close partnership we have enabled our clients to achieve significant cost savings by identifying product lines whose returns against sales cannot justify the high costs incurred in maintaining the necessary labour resources, inventory or indeed “floor-space” within their own manufacturing and storage facilities.

By transferring these product lines to our unit in Wiltshire and allowing us to undertake ALL manufacturing process for them, our client has successfully achieved:

- A reduction in his costs.

- Reduced Inventory.

- Reduced administration costs.

- Increased in-house capacity.

- Reduced lead times.

- Increased Profits.

Placing their business with Jetway our clients have benefited by our favourable “break-even” costs, (compared with their own) plus the additional benefits of dealing with a single supplier, who undertakes responsibility for all production planning, purchasing, manufacturing and despatching of the complete product lines to agreed prices and delivery schedules.

Here at Jetway Associates Ltd we have the experienced management team, the skilled workforce and dedication to our customers to say with confidence, “if you are considering Lean Manufacture, then consider Jetway Associates Ltd to be your partner in this exercise”.